In the realm of industrial equipment, the efficiency and reliability of cooling systems are paramount. Trane, a name synonymous with quality in the HVAC industry, offers a cutting-edge solution with its microchannel coil technology. When it comes to maintaining peak performance, the need for Trane microchannel coil replacement is a strategic consideration for industries relying on these advanced cooling systems. This article explores the importance of Trane microchannel coil replacement, highlighting the key factors and benefits that contribute to the optimization of industrial cooling processes.

Trane Microchannel Coil Technology: A Brief Overview

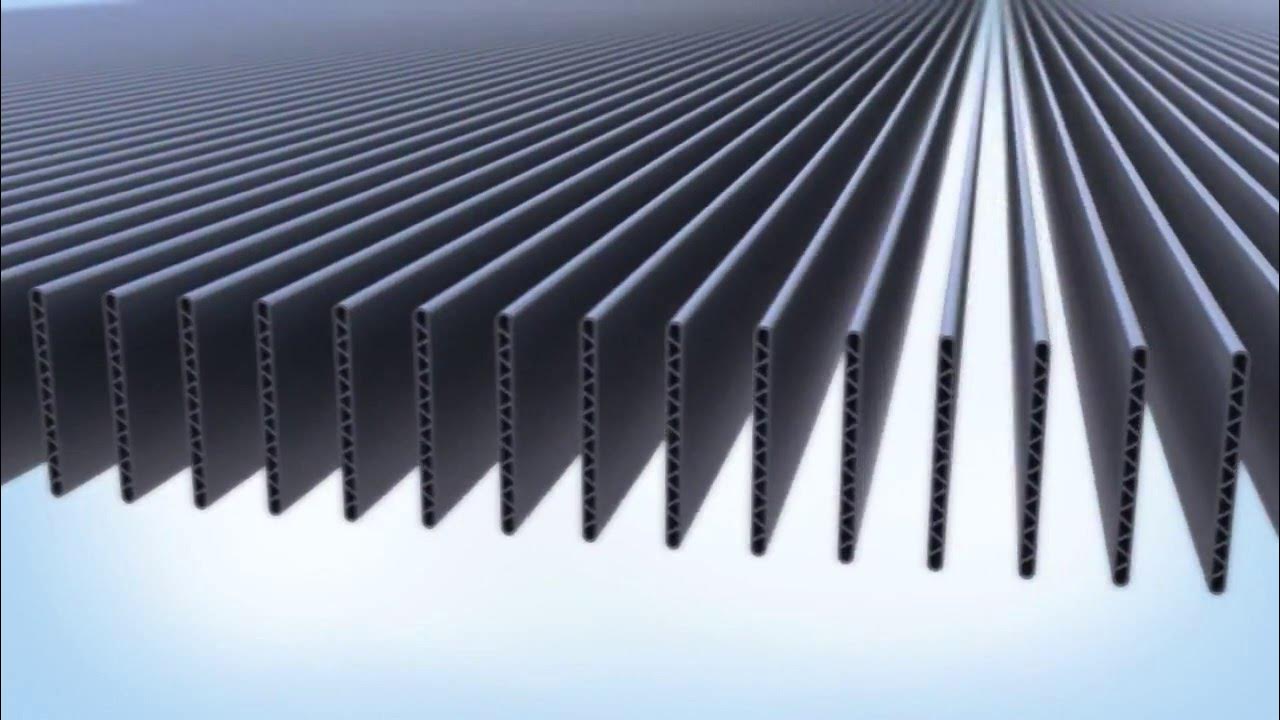

Trane’s microchannel coil technology represents a leap forward in industrial cooling systems. The microchannel design enhances heat transfer efficiency, allowing for more effective cooling in a compact and lightweight form. This technology has become a cornerstone in various industrial applications, from manufacturing processes to data center cooling.

The Need for Trane Microchannel Coil Replacement

Over time, industrial equipment, including Trane microchannel coils, may experience wear and tear due to factors such as usage, environmental conditions, and operational demands. When the efficiency of the cooling system starts to decline, or if issues like leaks and corrosion arise, it becomes imperative to consider Trane microchannel coil replacement to maintain optimal performance.

Key Factors for Trane Microchannel Coil Replacement

Efficiency Enhancement:

The primary objective of Trane microchannel coil replacement is to enhance the overall efficiency of the cooling system. Newer coils may feature design improvements and technological advancements that contribute to better heat transfer, resulting in improved cooling performance and energy efficiency.

Adaptability to Evolving Needs:

Industries are dynamic, and cooling requirements may change over time. Trane microchannel coil replacement allows for the adaptation of cooling systems to evolving industrial needs. Upgrading to newer coils ensures that the cooling capacity aligns with the current demands of the industrial processes.

Extended Equipment Lifespan:

Regular maintenance, including timely Trane microchannel coil replacement, contributes to the extended lifespan of industrial cooling equipment. By addressing wear and tear promptly, industries can avoid more significant issues and disruptions, ultimately maximizing the longevity of their cooling systems.

Environmental Considerations:

Trane, as a leader in sustainable HVAC solutions, often introduces eco-friendly advancements in its technologies. Upgrading to newer microchannel coils may present environmental benefits, such as reduced refrigerant usage or improved energy efficiency, aligning with the growing emphasis on sustainability in industrial practices.

Benefits of Trane Microchannel Coil Replacement

Improved Heat Transfer Efficiency:

Newer Trane microchannel coils are designed to offer enhanced heat transfer efficiency. This improvement translates to more effective cooling processes, ensuring that industrial equipment operates within optimal temperature ranges.

Space Optimization:

The compact design of microchannel coils contributes to space optimization in industrial settings. Replacement coils maintain this advantage, allowing industries to make the most efficient use of available space without compromising on cooling performance.

Reduced Downtime:

Timely Trane microchannel coil replacement helps minimize downtime associated with cooling system malfunctions. Proactive maintenance and replacement strategies ensure that industrial processes continue seamlessly, avoiding costly disruptions.

Energy Efficiency Gains:

Upgrading to newer microchannel coils may result in energy efficiency gains. This is particularly crucial for industries striving to reduce energy consumption and operating costs while adhering to sustainable practices.

Considerations for the Replacement Process

Professional Assessment:

Before initiating Trane microchannel coil replacement, it is essential to conduct a professional assessment of the existing cooling system. This evaluation helps identify specific issues, determine the compatibility of replacement coils, and ensure that the overall system is optimized for performance.

Compatibility with Existing Components:

Replacement coils should be compatible with existing components of the cooling system. Trane provides a range of options, and selecting the right coil model ensures seamless integration with the rest of the equipment.

Adherence to Manufacturer Guidelines:

Following Trane’s guidelines for replacement procedures is crucial. Adherence to manufacturer recommendations ensures that the replacement process is carried out correctly, minimizing the risk of operational issues and preserving the warranty on new components.

Conclusion

Trane microchannel coil replacement is a strategic investment in the efficiency and longevity of industrial cooling systems. As industries evolve, the need to optimize thermal management processes becomes increasingly critical. Upgrading to newer microchannel coils not only addresses performance issues but also positions industrial facilities at the forefront of efficiency, reliability, and sustainability. In the pursuit of operational excellence, Trane microchannel coil replacement stands as a testament to the commitment to quality and innovation in industrial cooling solutions.